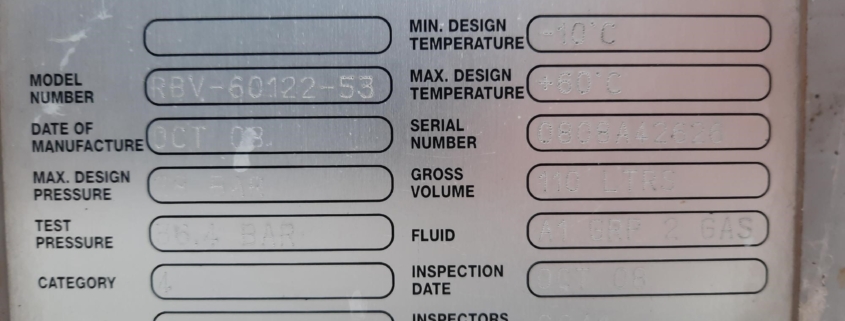

Stanref International Limited Pressure Vessels

Stanref International Limited

Northern Way

Bury

St. Edmunds

Suffolk

IP32 6NL

United Kingdom

Telephone : (01284) 763501

Pressure Vessel Industry News….

STANREF INTERNATIONAL LIMITED/Stanref International (2017) Limited

The company, founded in 1982 and based in Suffolk, is sadly insolvent.

STANREF INTERNATIONAL LTD had been a leading manufacturer of pressure vessels and heat exchangers for the commercial & industrial refrigeration industries since 1982. Over the next decade they also targeted the Oil & Gas, Petrochemical and Process sectors and saw their presence in these markets expand steadily; they finally closed their doors in March 2018. Abbott and Company manufacture many of the products they produced and have helped out many clients needing a similar product.

Their pressure vessel product range encompassed all requirements of the refrigeration market and included Shell & Tube Heat Exchangers, Liquid Receivers, Oil Separators, Surge Drums, Oil Recovery vessels etc.

They regularly designed and manufactured bespoke products to meet customers’ specific requirements, pressure vessels and heat exchangers for other industries including water process, compressed air driers, pneumatic powder handling, etc., and were regular suppliers to refrigeration contractors for the Royal Navy.

Stanref also produced Heater Shells and Filtration vessels for their Oil & Gas, Petrochemical and Process customers, in addition to De-Sander and De-Oiler vessels, often incorporating a hydro-cyclone design.

DESIGN & MANUFACTURE

Stanref International had a 2044 sq.m. factory located in the historic Suffolk town of Bury St. Edmunds, with all design and manufacture carried out in accordance with ISO 9001:2008 Quality Assurance System, and the majority of their products were produced in accordance with the Pressure Equipment Directive – Dir.97/23/EC – and CE marked where applicable, up to full ‘Quality Assurance’ Module H and H1 conformity. Stanref also held an ASME U1 Certificate with National Board authorisation.

Mechanical design was carried out using either the PV-Elite software package or their in-house design programmes, in accordance with PD5500, ASME VIII Div. 1 or TEMA as appropriate, thermal design with the Aspen EDR software package, backed up by tried and tested empirical data gathered from extensive testing; they also ran several AutoCad and Draftsite 2d stations, with additional Solidworks 3d design capabilities

Stanref had an in-house package fabrication facility, from which they regularly supplied refrigeration surge packs, compressor refrigeration packs and other bespoke equipment to customers’ own designs.

They were members of both The Welding Institute and the British Refrigeration Association.

Stanref had the following capabilities and capacities.

Office & Production

- Autodesk Autocad PLUS Solidworks 3D Software

- PV-Elite Vessel Design

- Aspen EDR Thermal Software

Capacity

- Diameter Range 100mm – 3000mm

- Maximum Length 12m

- Maximum thickness 50mm

- Maximum Weight 10 Tonne

Lifting

- 3 x 5 Tonne Gantry Cranes

- 7 x 1 Tonne Pillar Cranes

- 1 x 5 Tonne Forklift

- 1 x 3 Tonne Forklift

MATERIALS AND WELDING

Stanref International Product Range included:

CONDENSERS

Shell & Tube heat exchangers for Ammonia, Freons or carbon dioxide CO²

Marine (Cupro-Nickel)

Stainless Steel

Stanref International Also made Heat exchangers in various formats

Intercoolers, Oil Coolers, sub Coolers, Liquid to Liquid, Suction to Liquid, Stainless Steel, Steel/Copper, Accumulator, Desuperheater, Flooded Evaporator

MISCELLANEOUS products

Compressor Packs:-

Freons & Ammonia, valve stations, Vessel packs, Surge Drum & Pump sets, Chilled Water Packs

Glycol & Water Tanks:-

Mild Steel, Stainless Steel

Frame work

General Fabrication

Stanref range of international CHILLER BARRELS included

Shell & Tube – fixed tubesheet or ‘U’ Bundle

Stainless Steel

Brine, Glycol etc.

Stanref International Pressure Vessels included:

For Ammonia, Freons or carbon dioxide CO² :

Accumulator

Economiser

Intercooler

Low Temperature

Oil Rectifier

Oil Separation

Pump

Receiver

Surge Drum

Heater Housing

Large Air Receiver

Standard (Ex-Stock) Receivers

LIQUID LEVEL

Headers, Controls & Indicators, Float Switches, Sight Glasses, Level Columns

Stanref International ex Stock Receivers

8″ N.B. – 30 litre, 40 litre & 54 litre

10″ N.B. – 54 litre & 105 litre

12″ N.B. – 105 litre

Refrigerants CO² / Ammonia / Freon

Materials Carbon steel, Stainless steel, Cupronickel, Duplex, Brass

Material thicknesses 50mm

Total weights 10 Tonnes

Total overall sizes 3m Ø x 10m long

Types of welding TIG / MIG / MMA / SAW

Approvals ASME VIII Div.1 / ISO 9001:2008

Fabrication Equipment

- Flame & Plasma profile cutting

- Tube Bending

- Semi Automatic Shot Blasting

- Manual 20ft x 8ft Shot Blasting Enclosure

Subcontract

- Radiography

- Ultrasonic

- MPI & DPI

- Hardness Testing

- PMI

- Post Weld Heat Treatment

- High specification painting

Some of Stanref international Projects included:

| DESCRIPTION | PROJECT | END USER | CONTRACTOR |

| 2 x 10″ NB Heater Housings (316L) | Montrose BLP Project, North Sea, UK | Talisman Energy | Marubeni Oil and Gas Ltd |

| 1 x 14″ NB Heater Housing (CS) | Stella Field, Harrier Field & Hurricane Field, North Sea, UK | Ithaca Energy | Petrofac |

| 17 x Heater Housings varying in diameters

(CS & 304L) |

RasTanura Integrated Project (RTIP), Saudi Arabia | Saudi Aramco &

Dow Engineering Company Ltd |

KBR |

| 3 x 24″ NB Oil Separators | Eskene WEST Rail Project (EWRP), Kashagan

AGIP Kazakhstan North Caspian Operating Company, Kazakstan |

Agip KCO (Eni Spa group) | Worley Parsons |

| 3 x 36″ NB Flooded Evaporators | |||

| 3 x 18″ NB Thermosyphon Oil Coolers | |||

| 3 x 60″ NB Liquid Receivers/Economisers | |||

| 3 x 18″ NB Suction Line Heat Exchangers | |||

| 3 x 10″ NB Oil Pots | |||

| 3 x 24″ NB Float Vessels | |||

| 5 x Heater Housings (321 and 304L) | Kinef Project, Kirishi, Russia | Kirishinefteorgsintez | Kirishinefteorgsintez |

| 2 x 16″ NB Heater Housings (316L) | Manora Field Development, Thailand | Pearl Energy Ltd | Technip |

| 1 x 6″ NB Heater Housing (CS) | LP Associated Gas Compressor Piping Modification Project, Bapetco, Egypt | Bapetco & Shell | ENPPI |

| 2 x 12″ NB Fuel Gas Coalescers | Golden Eagle Area Development, North Sea, UK | Nexen Petroleum | Nexen Petroleum |

| 2 x 6″ NB Simplex T-Type Filters (CS) | EVA Plant & Utilities Project, Jubail, Saudi Arabia | Saudi International Petrochemical Co (Sipchem) | WEIR LGE Process |

| 4 x 34″ NB Heater Housings (CS) | Al Toukhi, Saudi Arabia | Al Toukhi | Al Toukhi |

| 4 x 24″ NB Heater Housings (CS) | |||

| 11 x 18″ NB Marine Condensers | CVF-Queen Elizabeth Class Aircraft Carriers-HTMS Ship 2 | British Royal Navy | BAE Systems Surface Ships

Thales Group Babcock Marine |

| 11 x 18″ NB Flooded Evaporators | |||

| 11 x 26″ NB Oil Separators | |||

| 1 x 36″ NB Condenser | VC3 Plant, Runcorn, UK | INEOS Chlorvinyls | INEOS Chlorvinyls |

| 2 x 14″ NB Oil Coolers | |||

| 1 x 18″ NB S&T DX 2-CC Economiser | |||

| 1 x 72″ NB High Pressure Receiver | |||

| 1 x 72″ NB Knock-Out Vessel | |||

| 36 x 12″ NB Crude Oil Heater Skids (CS) | Riyadh Power Plant No.10 Project, Riyadh, Saudi Arabia | Saudi Electricity Company | Arabian Bemco Contracting Co. Ltd. |

STANREF INTERNATIONAL LIMITED

NORTHERN WAY

BURY ST. EDMUNDS

SUFFOLK

IP32 6NL

UNITED KINGDOM

Telephone : (01284) 763501

We manufacture Great British Pressure Vessels, Heat Exchangers, Blowdown Vessels, Flash Vessels, Accumulators, Buffer vessels, Expansion Vessels, Surge Vessels and Air Receivers. Please do get in touch with any enquiry that you have.

Give Abbott a call on +44 01636 704208 or email info@abbottpressurevessels.co.uk

It’s good to talk!

Leave a Reply

Want to join the discussion?Feel free to contribute!